With 25 locations worldwide, Zollner Elektronik AG is a leading provider in the field of Electronics Manufacturing Services (EMS). To meet the growing demands of the industry, a state-of-the-art cleanroom area was established at the Vác site in Hungary. This expansion enables production processes to be carried out under strictly controlled conditions at the highest technological level.

For this project, Lindner Clean Room Technology was responsible for the interior fit-out of the cleanroom, while the installation was carried out in collaboration with our long-standing local installation partner. To allow for flexible room configuration, the Multiclean CLVT cleanroom partition wall, a modular wall system, was used. This system partition wall is complemented by the Clip K3 cleanroom ceiling, which ensures an airtight seal while also allowing for easy maintenance of the technology installed above.

SH-LED cleanroom luminaires provide optimal lighting conditions, while the Swing MPH cleanroom doors, in combination with the Inline 2 locking system, ensure secure, contamination-free access control.

To regulate the cleanroom climate, Filter Fan Units (FFU) were installed, providing a constant supply of filtered air, supported by a high-performance heat exchanger for precise climate control.

Project: ZOLLNER Elektronik Kft.

Building Type: Clean rooms (electronics and semiconductor technology), Production Facilities

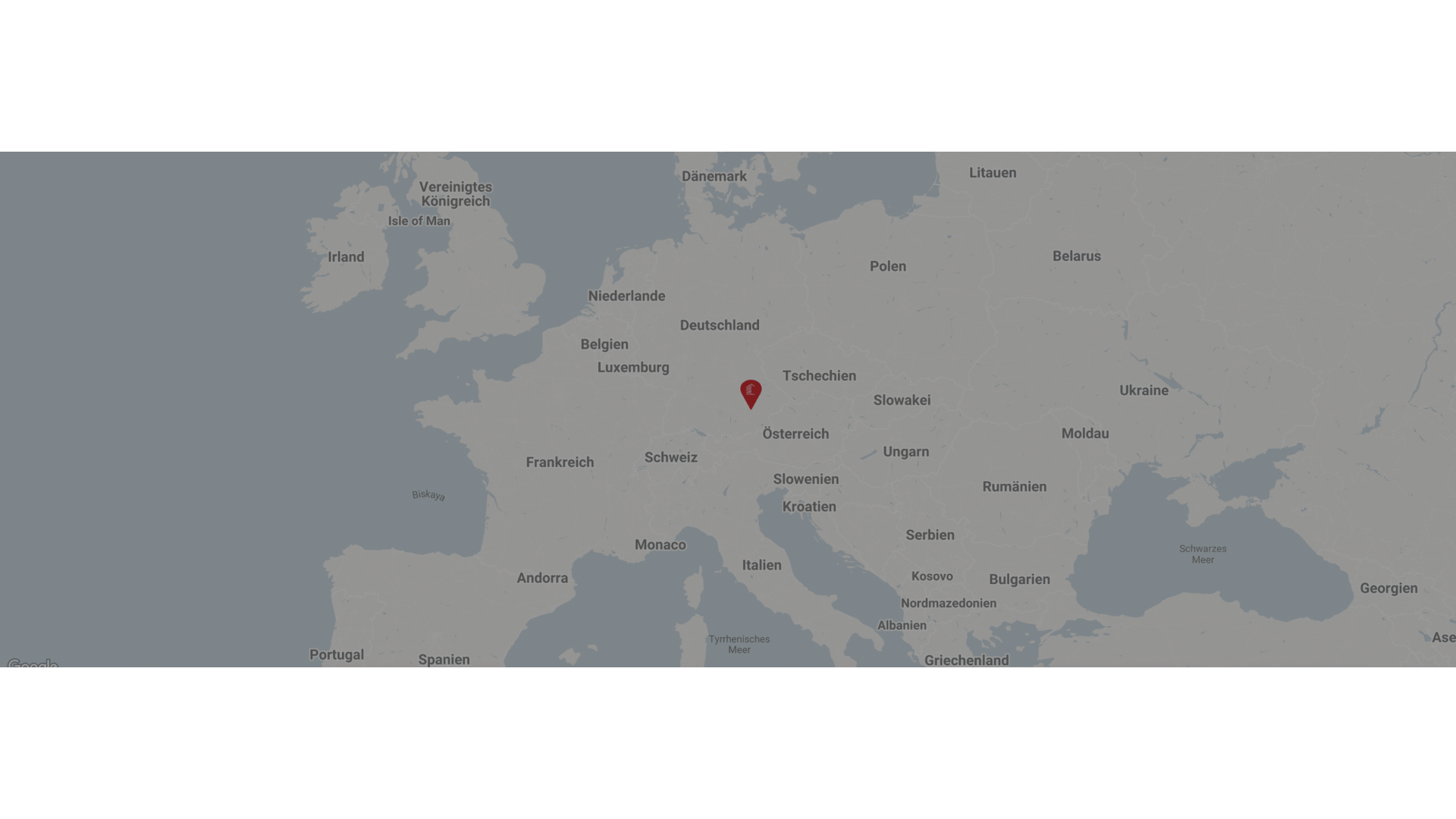

Address: Deákvári fasor 16-18

Zip/City: 2600 Vác

Country: Hungary

Completion: 2024

Company: Lindner SE | Clean Rooms

Client: ZOLLNER Elektronik Kft.

Clean Room

Partition systems 100

Clip-in cassette systems

Integrated lights

Hinged doors

Supply air

Door interlocking systems