Today's architecture demands innovative and sustainable building materials that fulfil both aesthetic and functional requirements. The solution to this is our glass fibre reinforced concrete, LinCrete: Since LinCrete was founded in 2018 near the headquarters in Arnstorf, Lower Bavaria, Lindner has been manufacturing and supplying high-quality glass fibre reinforced concrete elements, tailored specifically to the individual wishes of our customers. Due to increasing demand, the capacity of our first small production facility in Padersberg was soon reached. In May 2020, the management therefore acquired a second-hand commercial property in Kolkwitz and adapted it to meet the complex production requirements.

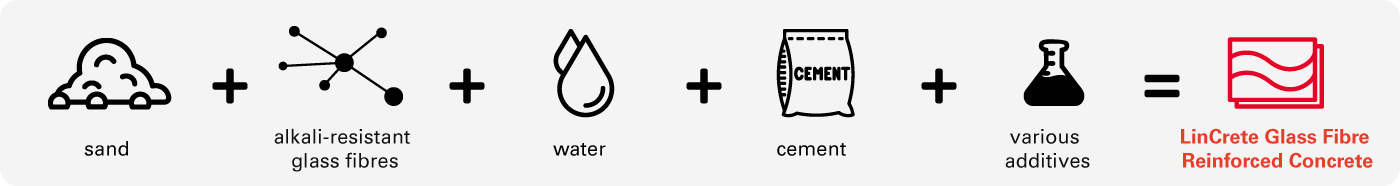

Glass fibre reinforced concrete, or GFRC for short, is a fine concrete bound with cement and reinforced with 2.5-5 % alkali-resistant glass fibres. The addition of these fibres enhances both ductility and stability while allowing for reduced wall thickness. These properties, combined with a carefully optimised mix formula, enable the creation of complex and unique shapes and geometries that would be unthinkable with conventional concrete. Whether in terms of shape, colour, or structural and acoustic requirements, Lindner offers almost limitless possibilities to bring our customers' visions to life.

Glass fibre reinforced concrete offers a range of advantages over traditional concrete, making it particularly attractive for specific construction applications and architectural designs: